Case Studies: Successful Implementations of Robotic Technologies

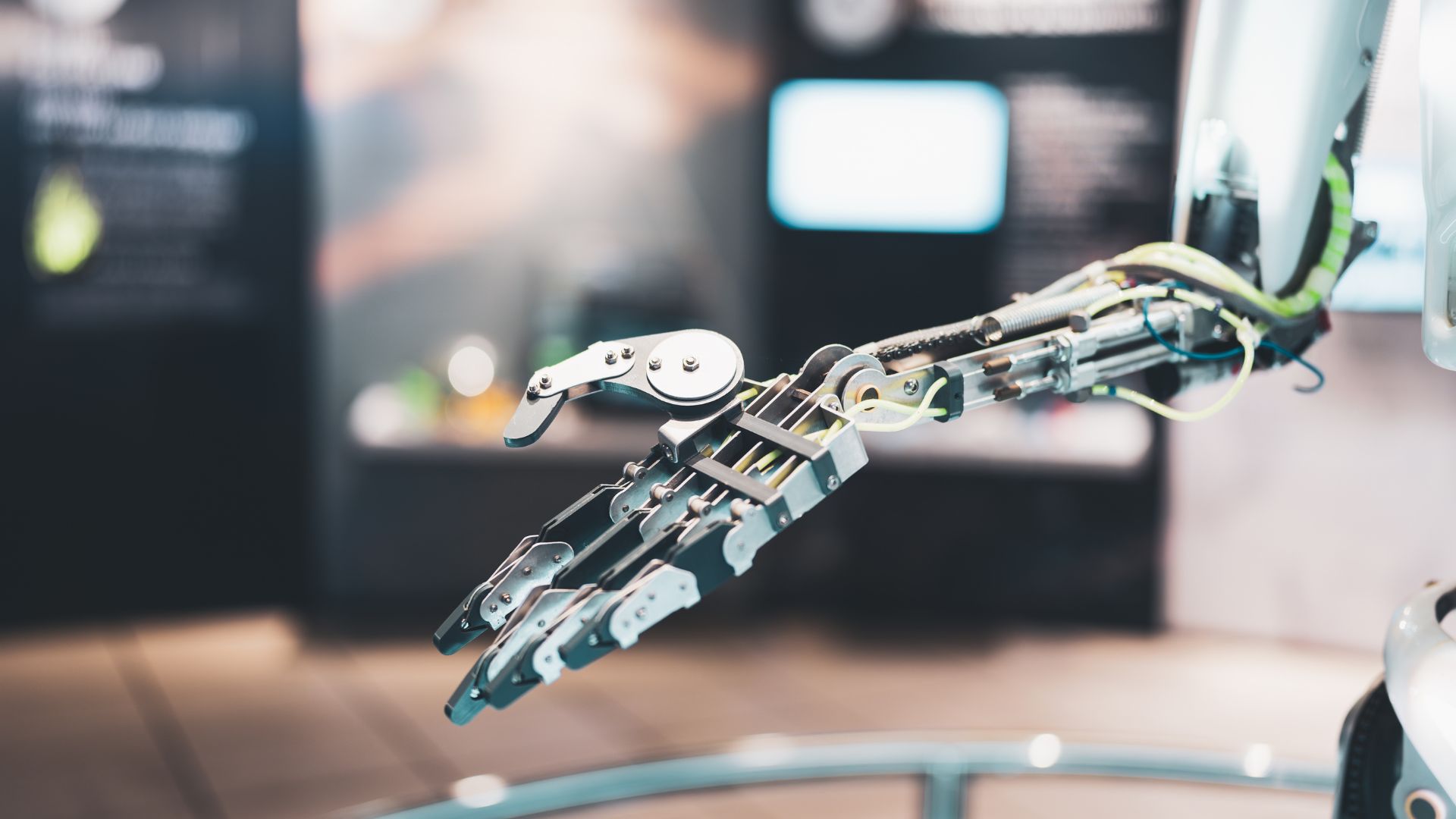

Real-world case studies of robotic technology implementations provide a glimpse into how these innovations are reshaping industries. One notable example is the use of robotics in the automotive sector. Major car manufacturers have integrated robotic arms capable of welding, assembling, and painting vehicle parts with incredible precision. These robots work alongside human employees in a collaborative manner, improving efficiency and production rates without compromising safety.

In the medical field, robotic-assisted surgery systems have redefined patient care. The introduction of surgical robots like the da Vinci system has enabled surgeons to perform minimally invasive procedures with enhanced precision. This has led to faster recovery times for patients, reduced risks of complications, and improved overall outcomes. Hospitals that have adopted such technology often report a significant increase in both patient satisfaction and procedural success rates.

The food industry has also benefited from robotic innovations. Companies have introduced robotic solutions for sorting, packing, and quality control, ensuring that products meet safety and quality standards. Robotic arms equipped with sensors can detect inconsistencies, remove defective items, and help maintain consistent production. This not only reduces food waste but also improves the speed and accuracy of processing lines.

These case studies illustrate the successful integration of robotics across various industries, demonstrating how technology can be used to optimize processes, enhance precision, and improve productivity. As more sectors experiment with robotic solutions, new case studies will continue to emerge, providing valuable lessons on effective implementation strategies and best practices.